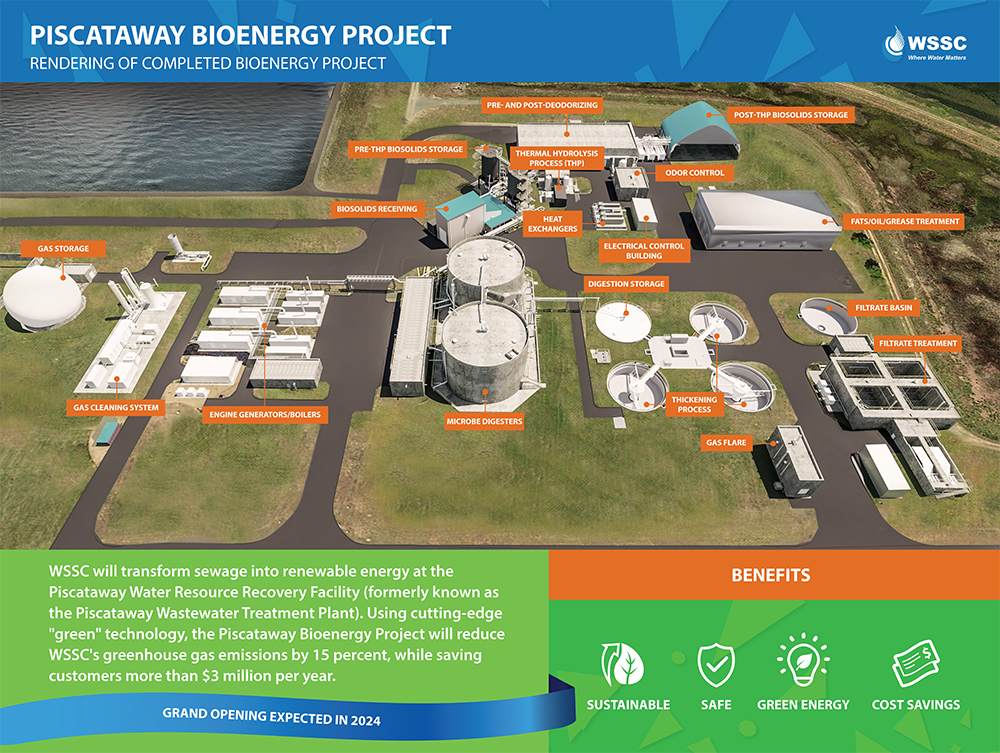

Curtis Power Solutions was selected by water and wastewater utility titan WSSC Water and PC Construction to provide design services and equipment that will service a new facility that treats biosolids from regional water resource recovery plants. The new Piscataway Water Resource Recovery Facility in Accokeek, Maryland will be finalized in 2024 and will feature a new 4.5 megawatt Combined Heat and Power (CHP) system designed to save customers money and create renewable energy.

This is WSSC’s largest and most technologically advanced project, and required the services of a power generation expert. Curtis Power Solutions VP of Power Gen Sales & Engineering – North Region Alan Koch explains, “Our team has provided power generation services to WSSC for more than two decades. We have provided at least 25 new generators for 90 sites during that period of partnership. Additionally, we have extensive experience with large-scale CHP systems, and understand the complexities of the design, the equipment, and the operation of these systems. Our knowledge of WSSC combined with our experience with high-profile CHP projects have been great assets in this Design-Assist project.”

Biogas Treatment: Why and How?

Traditional wastewater treatment of biosolids involves flaring off the biogas that is emitted from the treatment system into the environment. This biogas is wasted potential energy and an environmental contaminant. A CHP/Boiler/Gas Cleanup system can convert this biogas waste into renewable gas: a greener form of natural gas. When completed, the WSSC CHP system will clean the biogas and process it to create steam. The steam will then be processed to create renewable natural gas. This bio-energy gas will be sent back to the facility’s gas grid to fuel the facility’s energy needs.

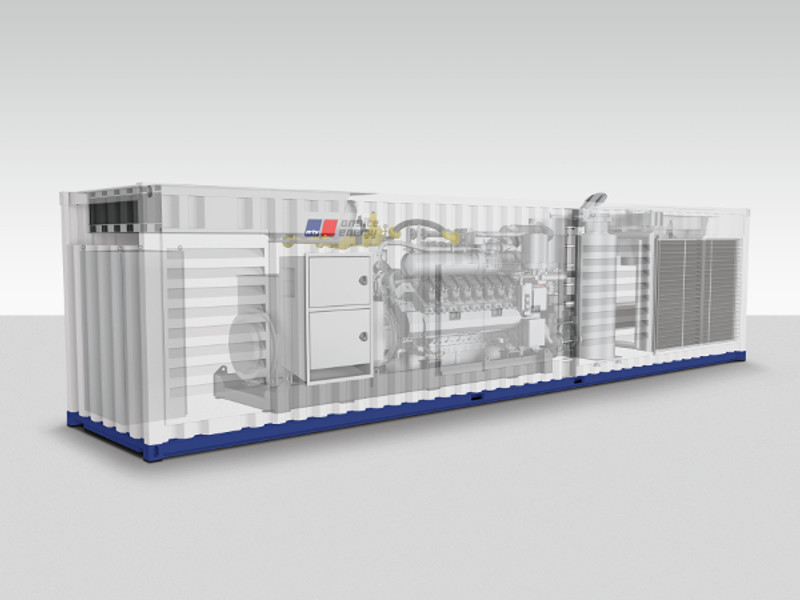

Curtis Power Solutions is providing this WSSC project three 1550kW CHP generators with custom enclosures and three boilers in custom containers.

Challenges and Solutions

Covid-19 restrictions were one of the major challenges in the project design stage in 2020. Site visits in Maryland were impacted. Traditional in-person design and construction team meetings were affected and moved to 100% virtual. These unforeseen speed bumps obstructed scheduling and other critical aspects of the project. Fortunately, the Curtis Power Solutions business is based on the necessity for agility and creative work-arounds, so this experience in streamlining processes combined with the close working relationship with generator system manufacturer MTU kept the schedule moving.

.png)